Feeder mixer blades Frielo® Plan

Feeder mixer wagons usually have one or several augers

with different gradients. Because of the continuous

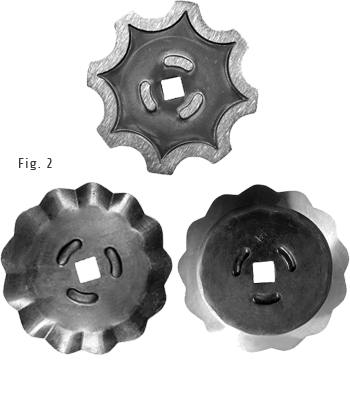

gradient of the auger the latter does not show an even surface at any place. The knives, however, are all even. When fi tting the knives these rest, at fi rst only on separate points on the auger (see fig. 1).

By tightening the knife fi xing screw, the knife is tensioned

by force until it has fi nally adjusted itself to the auger.

In order to make this possible at all, the hardness of

the knife has to be very low (48 HRC max.) The result

is, of course, a high wear of the knives; this is especially

unwanted in the case of feeder mixing wagons,

since the changing of the knives is associated with a

high effort.

Moreover, the changing of the knives is an accidentprone

routine.

In order to solve or at least reduce the above mentioned problem, FRIELINGHAUS has switched from overall tempering to partial inductive heat treatment of the cutting edge area. Through this procedure the hardness could be increased to 56 HRC, where it is needed, at the cutting

edge. As a result the wear resistancehas considerably improved.

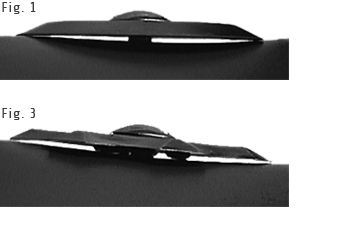

With the Frielo® Plan model presented here, FRIELINGHAUS has achieved the optimal solution. Based upon the idea of a three-legged milking stool standing safely on all, even extremely uneven surfaces, the knives are equipped on the surface with three deepened imprints which protrude as elevated supports on the blade side

(see fig. 2).

The knife is resting with the 3 supports only on the auger (see fig. 3) and is therefore not tensioned in any form, so that the hardness can now be increased to more than 60 HRC. This hardness on the cutting edges allows an excellent wear and tear thus resulting in a maximum life span of the knife.

We hold a patent on the Frielo® Plan system.