Feeder mixer blades Frielo® Spike

Individual or several blades rotating on the auger may particularly occur in horizontal feed mixing trailers due to different loading quantities and consistencies of the different ingredients, as well as due to wear of the blade edges during the mixing process. This unnecessarily increases the force and energy required for the cutting and mixing processes. Furthermore, it may happen that none of the cutting edges of blades with several cutting edges is located in the proper angle on the auger, and therefore might end up with no cutting effect at all.

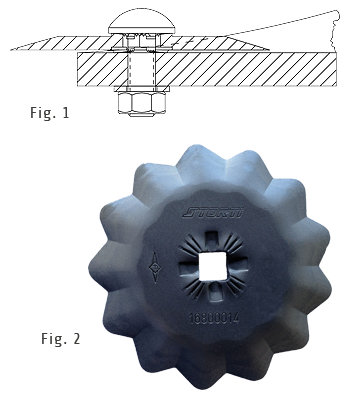

After having reached a certain service life, the cutting edges of the blades are blunt so that the cutting forces increase and satisfactory cutting results are no longer provided. The blade is now loosened on the auger and rotated to a new cutting position. After the cutting edge was replaced, the fastener is re-tightened so that the blade is located in a defi ned position in relation to the auger and the mixing auger can be operated again (see figure 1).

Frielo® Spike ensures that the blade does not rotate

by itself on the mixing auger with the help of a secure

fastening system, forming a toothing as part of the

blade, with this system meshing with the basic material

of the underground when the blade is attached

(see figure 2).

Frielo® Spike increases the force required for twisting by as much as 70% (85N to 140N)!

Frielo® Spike can be attached both to the lower side and to the upper side and even simultaneously to both sides. This way, attachment is provided for both on top and below the mixing auger (see figure 3).

Frielo® Spike can be used in connection with all drilled blades where reliable attachment and twisting protection are important.

Frielo® Spike can be attached both around a drilled hole and to the individual sides of a drilled hole (see figure 4).