Frielo® Safe disc mower blades

The advantages

Conventional disc mower blades are made of boronsteel or chrome vanadium or nickel chromium steel.

Frielo® Safe disc mower blades are manufactured

from an especially for FRIELINGHAUS melted special

boron-steel with an increased portion of carbon and

chromium. This results into the following advantages:

1. High wear resistance due to the chromium and silicone

carbides, for a long operating life and lower costs per hectare.

2. Ultimate tensile strength and high fl exibility is achieved through higher hardness after quenching and fine microstructure for maximum safety.

Frielo® Safe disc mower blades are manufactured in a fully automated, controlled production process - a favorable cost situation that keeps the price low.

Constant high quality

Constant high quality

Production is continuously monitored forquality assurance. This guarantees highquality products on a permanent basis.

All quality-related data is documented and archived for 10 years. The production mark impressed on each blade ensures traceability down to the last detail even over an extended period of time.

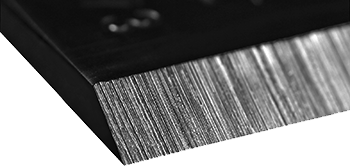

The cutting edges on Frielo® Safe disc mower blades are sharpened to a fi ne edge by grinding. The resulting clean cut protects the turf and promotes fast regrowth.

Therefore you are laying the foundation for the next high-yield cut by just mowing.

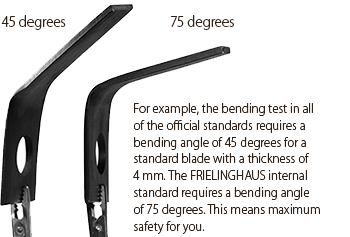

Maximum Safety

Frielo® Safe disc mower blades comply with all common national and international standards (ISO 5718, ISO 2768, ISO 6508, DIN 11250, DIN 7168 Part 1, DIN 50103 Part 1).The internal standard developed and practiced at FRIELINGHAUS even exceeds some of the requirements

of the offi cial standards.

Most of the well-known, large manufacturers of mowing equipment have their blades manufactured by the blade specialist FRIELINGHAUS. And they know why.

Frielo® Safe disc mower blades are continuously being developed and optimized in our own fi eld tests and in cooperation with mower manufacturers, steel mills and specialized institutes.